autonome

Product Management // Ethnographic Research // User Centered Design // Business Model Generation

The Master of Product Design and Development Management program at Northwestern University is defined by its year-long capstone project centered around “Designing For The Home”. As the students in the cohort are divided into teams based on experience, area of expertise, and location in the Chicagoland area, I was sorted into Team Aqua. Below is the journey of how Team Aqua researched a problem spaced, created a unique solution, and made it viable in the market.

Getting into trouble.

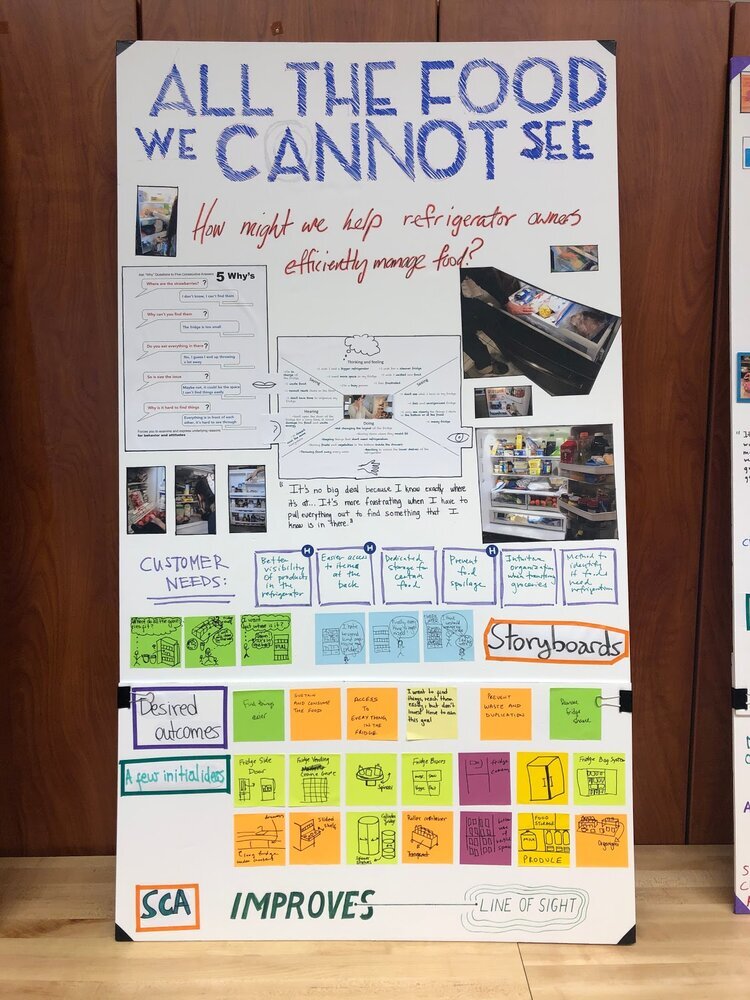

It all begins with getting into a little trouble…meaning that we had to observe and find problems around the home. Next, we narrowed our list down to three problems that we found most interesting. Then, we conducted ethnographic research across various different people and user groups. With this research, we analyzed and categorized our findings into models to help explain the findings. From here we chose the space we found most fruitful and continued conducting interviews, gathering data, and analyzing it all. Finally, with all the models, findings, and research we distilled down our data into three distinct insights for problem space.

Insights

Young cooks lack the skill and knowledge to prepare raw meat in a safe manner, so they feel suspicious and estranged from the meat and avoid it as an ingredient.

Young cooks find the preparation of raw meat a non-intuitive process. The mental load of recalling what was touched and what needs to be washed makes users exasperated, frustrated, and less inclined to cook.

Young cooks find the sensory experience of preparing raw meat unpleasant and distressing, leading them to engage in irrational avoidance behaviors triggered by their imagination

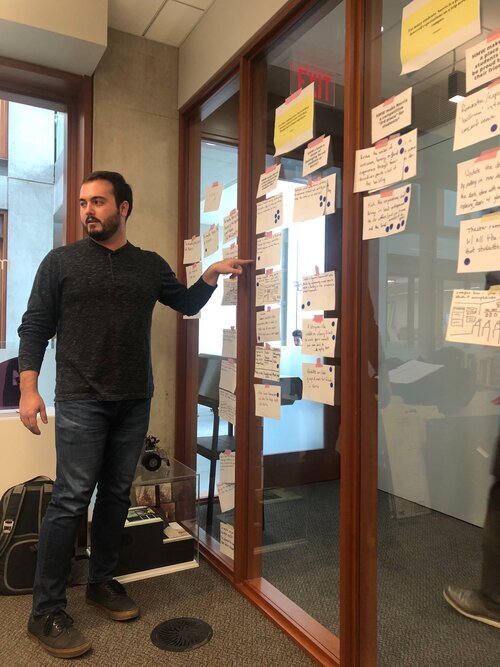

Ethnographic Research

Through three problem spaces, I observed people working with messes in their refrigerators, talked to tenants with noisy apartments, and watched cooks prepare raw meat. Without doing this kind of research, it is impossible to get a thorough understanding of the user (whom you’ll be designing products).

Raw Meat

We found that our raw meat preparation space was the most interesting and had the greatest potential for success. Though we focused on millennial’s mostly, this problem is not exclusive to younger folks. They are simply the generation with the most amount of people with this problem.

Ideate & Iterate.

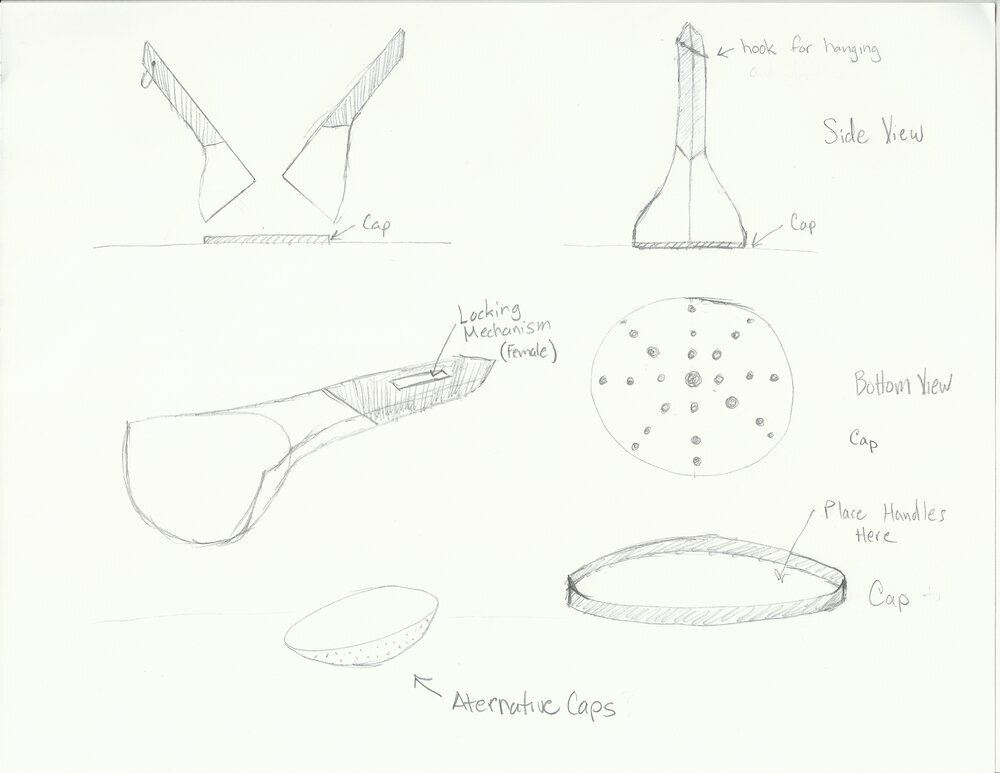

Once our problem spaced was defined and we knew who we would design for, we had to stretch our individual creative ids, make our team a place of “yes -and”, and learn that C+ Ri = Re. For me, stretching my creativity id meant learning to lead design and creativity. As a natural creative type, I had to learn to accept better ideas than my own and trust others to create.

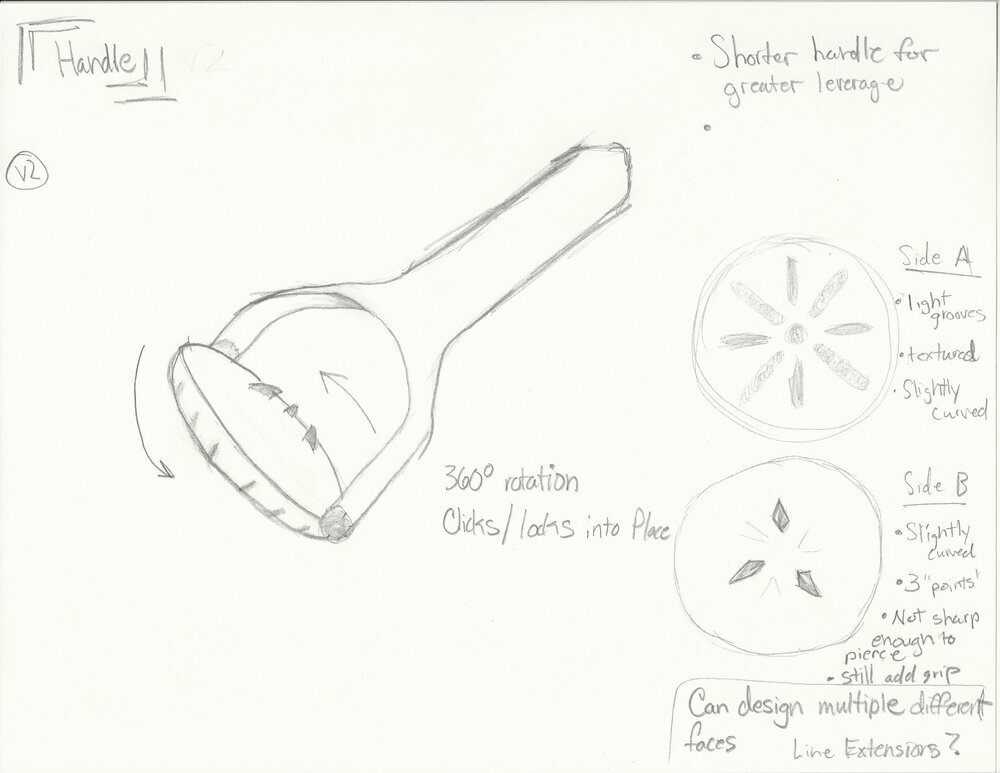

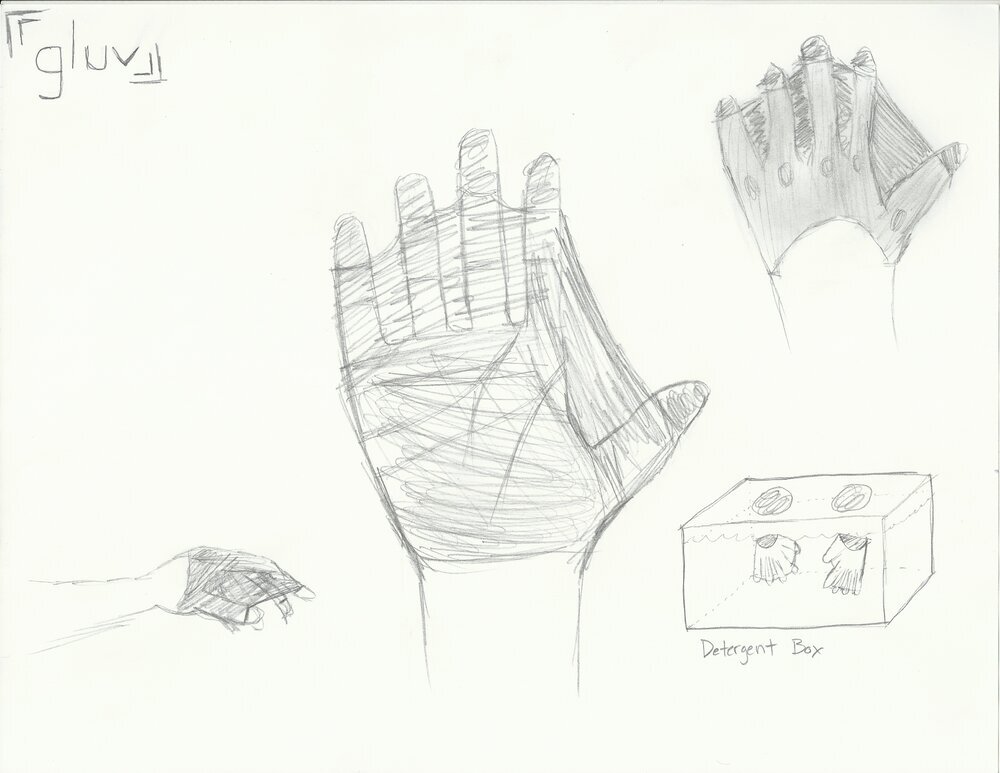

After getting into the right mindset, we used a vector map to guide our ideation. This was instrumental in directing our ideas to answer all the questions we were out to solve and solve them in a variety of ways. Our team set out on iterating on our ideas until we found something that we believed worked. To supplement the iteration, we prototyped and tested new kitchen tools and materials to see what worked and what was purely theoretical.

C + Ri = Re

Our professor wrote this equation for us. It means creativity plus risk will produce results. Prof. Dziersk always pushed us to get out of our comfort zones to take greater risks because it leads to more amazing things. He would also tell us that innovation doesn’t happen in isolation. It happens together as a group.

Raw Meat

So as we began iterating on our design in mid-March 2020, the world was taken over by the COVID pandemic. Naturally, this turned the world upside down and made our prototyping difficult since no one could leave the house. However, we pushed through and we able to test different techniques and designs with the resources we could find at home.

Bringing it to life.

Now that our team had a solution, we had to bring it to life. This meant making sure it was manufacturable, marketable, shippable and that we had a business plan and strategy on how to attack the market. As we learned the principles of Lean Design, we were simultaneously applying them to our product and making a bill of materials to fully understand the cost of the product.

When we finally had something we knew we could sell, we began the branding, marketing, and business portions of standing up the product. Our solution was given the name the “Meat Handler” under the brand autonome. Our tool came with an additional “Anchor” attachment because we envision The Meat Handler to have a future beyond just this particular use. Autonome was also given a brand identity as the brand to help convey the idea of independence in the kitchen.

To give ourselves a competitive edge in the market, we filed a provisional patent for the Grablock technology that would help mate the Anchor to the Meat Handler when attaching the two during use. This protection of Intellectual Property would help autonome to stay at the forefront of the kitchen tool industry.

Lastly, for our business plan we positioned ourselves as an entrepreneurial start-up and with a strategy to market primarily to millennials as they were the market that demonstrated the aversion to raw meat preparation most. Over time, our strategy would market to all segments because there was also great interest from other age segments.

Price

As the Meat Handler evolved, the bill of materials varied wildly. Originally, our offering was a kit with three tools. This meant much more material and therefore a higher price to ensure profitability.

After finalizing the the Meat Handler and understanding the expected margins from retailers, autonome decided The Meat Handler to be offered at $19.99 retail.

Business Plan

By positioning ourselves as a start-up, autonome can be lean to maximize profitability as soon as possible and has the flexibility to adapt to challenges as they arise. Lots of innovation happens in larger companies with big R&D budgets, however lean start-ups provide the freedom to develop a better product because of less red tape and bureaucracy.

It takes a village…or amazing team.

I wish I could say I did all of this by myself, but that would be wrong. Autonome, the Handler and Anchor, and all the related material were created by Team Aqua.

If you would like to see more detailed samples of work please contact me.